Here we have the final tests and setting of the supercharger. Although simple in operation, you can see the reason for attention to clearances. The rotor engagement and disengagement are so close, it is critical that we have the timing correct to give the full clearance available. In the video we are only doing about 500 rpm... less than 10% of the actual speed in the car!

We have set the clearances and tested them at three different temperatures, noting the results carefully to a chart. This will be an area to monitor carefully during initial test runs.

Note how my hand restricting the pressure loads the battery powered gun.

We have been waiting for one drive extension shaft bearing to complete the assembly and refit to the engine.

Please press the play arrow..

In the above, we have made a mandrel to mount supercharger spacer washers that we have previously "roughed out" from EN16 bar. We then finish skim very close to size with the use of the clocked mandrel which has a boss machined to the correct depth.

Final adjustment for the last "tenths of a thou" can be completed with an an oilstone if necessary.

We have been working on some finishing touches, including making some new studs where necessary and making an "indexing" oil flow control to the cylinder head. It is important that attention is given to this area as the use of a sporting cam and increase of RPM will increase the loads of the valve train exponentially. The original union has a fixed restricted path.

Some new studs have been machined as well as various items that had accumulated as "to do" during the build.

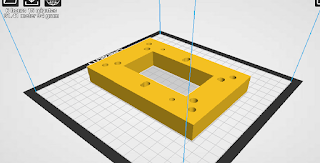

With the 3D printed concept, noted in previous posts.

Finished oil control indexing valve... missing the one spring that I had found just for this purpose. Last seen flying over my shoulder just before this photo!

Stud making.

Back to the drawing board, very annoying. The new duplex timing chain requires a wider tensioner. I thought my Tufnol strip rivetted on to the original steel would be a good idea, and it would have been fine in position. But trying to get it in and out of position, for slight alteration now that the chain is on, meant a little too much of a bend as I feed it down around the sprockets and chain! Back to a piece of wider spring steel strip will be a better idea I think.

As we've been waiting for bearings for the supercharger, we have used the time to revisit some areas that require further attention at some point before or after the brief initial test run.

Below, we are altering a Tufnol block chain guide (not the tensioner previously mentioned above) to sit into the bosses of the cylinder block timing chest. It is surprising how much bespoke work that has been necessary in the building of this engine.