We have not spoken about the Turner 950s Project very much on this blog.

It is a car that we have been working on for a number of years, although latterly the Wolseley has been taking most of our time. Here are some catch up photos of the Turner over quite a period. They are in no particular order and it has been a little difficult and time consuming to recover them from various devices. More up to date pictures will be added to this group before too long:

Work on an adaptor arrangement for the wooden rimmed wheel. Machine an internal taper and broach /hand finish a keyway and new key. Blue and lap the tapers.

Many replacement brackets. The wishbone items have been remodeled with a fold around flange. We feel this is an improvement should the car ever become modified for disc brakes in the future (we've opted to keep the original drums for the moment, complete with original race mods these have a story to tell).

Making uprated wishbone brackets and salvage the original pins and locking plates.

Recovery of a very nice wooden rim wheel.

Fettling and dressing steering column paintwork ready for the final coats.

As we are on the coast, it is important to get primer and paint on as soon as possible, we can then return to individual items to prepare and flat for the "nice" top coats later in the build and after the trial assembly work. The chassis looks quite dull at the moment because we coated it in waxoyl to protect. As the car approaches completion, we will clean these areas and be more selective where the Waxoyl is applied. We can also weld and alter as we need before attention to a complete cosmetic finish.

Next we have some dynamo work for a Dnepr outfit. Two dynamos, one for fitting and one for spare.

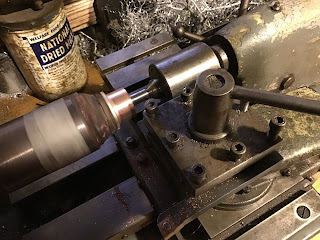

Below illustrates one bearing that would not move off the shaft. The journal portion of the shaft had been swaged so forcefully at some point that we had to machine the journal face below the bearing face to release the swaged portion. Further assistance was required with careful heat cycles

Slow undercutting process, the two units differed in the copper material machining properties.

Both armatures have considerable runout between centres!

Preparing to test. if all is well we will briefly back track and fit new bearings and brushes. Having been apart once this will be a very quick operation but as the unit were unknown we felt it best not to spend on parts until sure.

Wolseley Special Continues.

More of both projects as well as the Wolseley and some Studebaker to follow very soon

Below we have become quite modern for us, this is a 500cc single cylinder engine from a Honda agricultural quad.

The engineering is extremely good, but the engine is very complex with two clutches, balance shafts and multiple gear arrangements for different transmission situations. I have rebuilt more simple V12 engines than this!

If you look hard at some of the pictures, you might spot pistons rings and the odd gudgeon pin cirlip in the catastrophic piston failure debris.